The limits of transitional stone cleaning methods

Abrasive Cleaning Methods

In addition to biocides, traditional abrasive conservation methods used to remove various degrees of biological growth and carbon deposits have had challenges of their own. Abrasive methods like bristle brushes and pressurised water can attack both carbon and biological staining but have been known to damage the surface of stone. This reveals larger surface areas making the stone prone to accelerated build-up of biological growth after cleaning since spores have more places to settle on, which can undermine the effectiveness of the cleaning process and the economic argument for performing the cleaning to begin with.

Stone profile becomes rough because the abrasive method removes material unevenly, increasing the surface area and hence sites for biological spores to deposit on the wall, accelerating their regrowth.

Abrasive methods are by necessity time intensive, since they are performed relatively slowly in hope of making the cleaning process gentler and limit damage to the parent stone. However this results in long project durations, increasing required management time and associated running costs of the cleaning project.

Chemical cleaning with biocides

The alternative to abrasive methods as previously mentioned are biocides, chemicals applied to stone which kill and can inhibit bio-films. Where inhibitors can be active on the stone surface from a range of months to some years. Unfortunately, since organism susceptibility can vary, copious volumes of biocide can be required to target just a small fraction of biological species that are distributed over a wide area. Therefore excessive use of biocides to treat a relatively small population of bio-film makes risks of leeching products of harmful toxicity levels into surrounding water systems unjustifiable.

Alternatives to solution based biocides, are natural biocides such a copper. Copper metal is physically installed in strips into the mortar and oxidises over time to produce a natural biocide which despite being prone to leech from buildings is more environmentally benign. However, incorporation of foreign structures into the mortar can compromise the integrity of the masonry, moreover, the characteristic bluish-green of copper-oxide, can cause staining which in some cases is not aesthetically pleasing.

NOVEL LASER SOLUTIONS

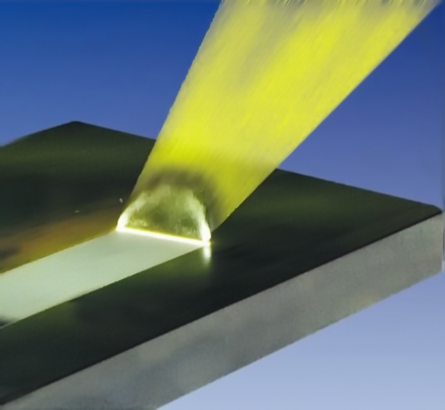

In response to challenges faced by conservationists, high and average power lasers have offered a new kind of capability. Masonry laser cleaning makes it possible to simultaneously clean carbon deposits and biofilms with a single laser system, unlike traditional solutions which may require multiple techniques. Moreover, the volume of residue produced during laser cleaning, the majority of which are airborne ablation by-products, are considerably less; lending themselves to capture and containment by deploying standard air extraction systems.

Contrasting with the cumbersome collection of waste sand from sand blasting, or the enigmatic recovery of liquid biocides laser cleaning solution enables users to conveniently control and quantify air-borne products limiting the environmental impact.

The versatility of our SWIPE laser cleaning solutions offered by lasermach allows laser parameters to be adjusted on the conservation site to optimise it for different masonry surfaces such as marble, sandstone, granite etc. without damaging the stone surfaces. Laser cleaning acts locally at the surface of the stone, hence avoiding destructive probing seen in abrasive methods or insertion of foreign objects which can compromise their mechanical integrity.

The ability of our SWIPE cleaning lasers to remove both carbon deposits and biological growth has significant implications for cleaning speeds and ease of processing. A single solution is required to remove both types of contamination and time is not spent recovering waste products from the environment after cleaning. Hazards involved such as laser light (visual) and ablation products (airborne) are either transient or conveniently controlled using standard air extraction, meaning the risks associated with this technique can be reliably controlled and quantified. This makes laser cleaning solutions simple to regulate and means users can confidently operate according to government policies.